The final frontier: how HENSOLDT is providing cutting-edge solutions in space

Key role in James Webb

The James Webb Space Telescope successfully launched on 25 December 2021 and began beaming back incredible imagery of our universe several months later. In this story, we discover more about how HENSOLDT – a leader in space-based technologies – played a key role in James Webb and how this experience in solving complex challenges is shaping future space-borne solutions for its customers.

Februar 24, 2023

info@hensoldt.net

CATEGORIES:

Space

Innovation

Optronics

The importance of space

Space plays a critical role in our lives. Satellites and spacecraft launched from earth perform various missions,for example research and exploration.

It also includes telecommunications, earth observation and global positioning. Of course, space activities also play a role in national security.

Space legacy since Apollo

Like space itself, HENSOLDT’s experience in this domain is vast. The company leverages its significant experience as an advanced sensor and component manufacturer, including in optronics and radar, to meet the extreme demands that space presents, whether that be in deep space or orbiting the earth.

“We are active in many different areas of space equipment and instrumentation.”

Kai Weidlich

Head of Space Technologies at HENSOLDT Optronics

Weidlich explained that the company can even trace its space legacy back to the US Apollo missions that landed the first humans on the moon, with stunning photographs taken with cameras fitted with optics from Carl Zeiss Optronics, a heritage HENSOLDT company.

A number of satellites that are currently in orbit around the earth – whether in low-earth orbit or geosynchronous orbit – have advanced HENSOLDT radar and optoelectronic components on board. This also applies to spacecraft that go deeper into space as part of missions that seek to learn more about our solar system and the universe.

HENSOLDT is supplying sensor elements for the European Space Agency’s (ESA) upcoming Jupiter Icy Moons Explorer (JUICE) mission, including the Ganymede Laser Altimeter (GALA). GALA – one of eleven scientific instruments on board – will be able to topographically measure Ganymede by orbiting the ice moon, and could even find out whether there is liquid beneath the surface.

James Webb – a revolution in deep space observation

A recent success for HENSOLDT – and a clear demonstration of its space pedigree and ability to successfully respond to complex challenges – is the involvement in NASA’s flagship James Webb Space Telescope (JWST) mission.

JWST is an “orbiting infrared observatory”, according to NASA, offering greater wavelength coverage and much higher sensitivity over the legacy Hubble telescope, which is now over 30 years old. The longer wavelength coverage allows astronomers to look far deeper into the universe, closer to the beginning of time when the first galaxies were formed.

Astronomers are effectively given a time machine, allowing them to look back billions of years. To achieve its mission, the JWST has four instruments on board, two of which were developed and built in Europe: MIRI and NIRSpec. The cryomechanisms and spectrally splitting optics elements of these instruments were designed and manufactured by HENSOLDT´s optronics division.

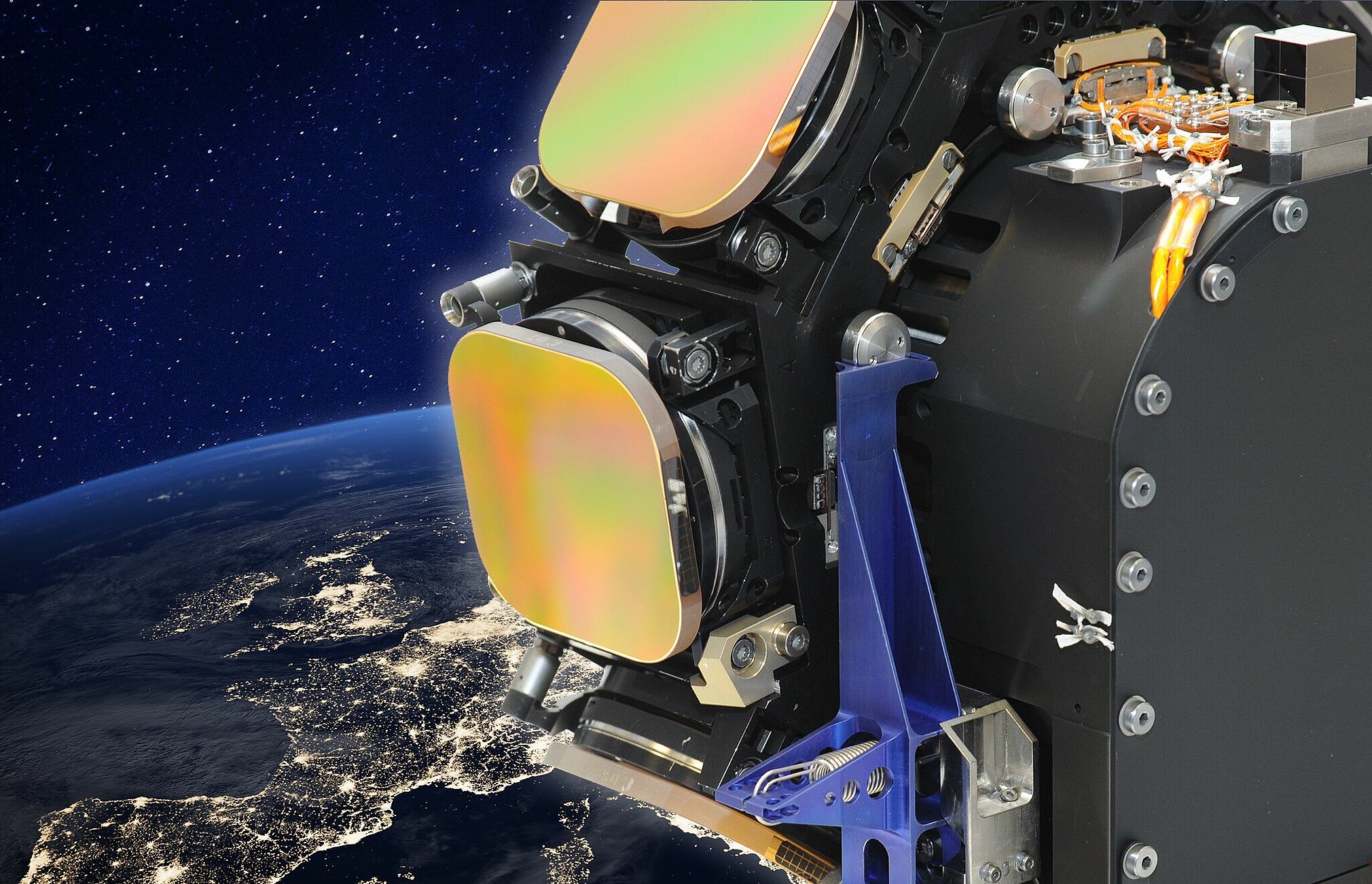

MIRI (see picture above) can detect light in the mid-infrared wavelength range between 5 and 28 µm, allowing Webb to detect light that has been “stretched” by space from visible to infrared, as well as to view space objects obscured by cosmic dust.

Meanwhile, NIRSpec (picture below) is Webb’s “workhorse” and enables light to be dispersed into different wavelengths, which is a first for a space telescope. This allows scientists to not just collect imagery, but also to find out the chemical composition of stars and how they were formed.

High reliability is key for space missions

Many of the critical hardware elements on board the JWST flew for the first time in space, presenting a number of technical engineering challenges for the teams involved. This required very high levels of reliability and guaranteed performance for each part of the instrumentation.

Any fault in space, however small, can compromise an entire mission and billions in investment could be lost. The mechanisms in a satellite’s instrumentation represent a single point of failure (SPF) that could have a knock-on impact, and there are usually many SPFs on a spacecraft.

Reliability is equally important for spacecraft that are used for deep space exploration, where they operate far into the solar system over several years and a quick pitstop for repairs is not possible!

Agencies such as NASA and ESA have strict standards in place to ensure space technologies are safe, reliable and perform how they should. These standards are similar to – but even stricter than – military standards, an area that HENSOLDT also has many years of experience in, both for radar and optical sensors. All satellites equipped with HENSOLDTs sensors have operated faultlessly and without failures, in some cases far beyond the originally planned service life of the systems, such as TerraSAR or TANDEM-X.

Surviving extreme space conditions

Space technical standards are critical to ensure that equipment performs as it should in the most extreme environments. These extreme environments start on earth when a rocket launches a payload out of the atmosphere and into space; the g-forces placed on equipment are beyond anything experienced on earth.

And the stress on equipment does not end once the satellite is in orbit, with temperatures dropping to -270 degrees Celsius and equipment also experiencing disturbances such as solar flares or coronal mass ejections from the sun. Going deeper into space, planets themselves can also interrupt the functioning of equipment. During ESA’s JUICE mission, for example, equipment on board must be protected as the satellite will pass through an intense radiation belt, a product of Jupiter’s strong magnetic field.

The success of JWST and the fantastic results already achieved from the onboard instrumentation clearly demonstrates that HENSOLDT successfully overcame many of these technical challenges.

Understanding the mission and providing solutions

HENSOLDT is first and foremost a solutions provider, whether on earth or in space, and its experience as a sensor house is directly applicable to space-based applications. Ensuring that customers have the right solution – using a range of technologies – that addresses their challenges is paramount.

“Starting from concept, it’s important to think about what is really needed to do a particular task in space, that’s why HENSOLDT has gradually evolved from a component business, to a subassembly and instrumentation business, and can now respond if somebody asks for a particular application or capability.”

Kai Weidlich

Head of Space Technologies at HENSOLDT Optronics

This is where experience matters and understanding how equipment performs and integrates into a wider system is key, especially when only one product is being built for launch. On many occasions, the initial design for a piece of space technology is very close to the final design, which is essential for complex projects such as JWST or JUICE.

This is made possible by the use of proven components and modern design technologies such as digital twins. The latter not only simulate the performance of the instruments and assemblies, but also how they perform under demanding launch conditions and operations in space.

“We have learned at HENSOLDT over the years that to really be successful in space we need to think about systems and instruments as a whole,” said Weidlich. “We have extended our capabilities with regard to getting together high precision mechanical engineering, optical and radar design and engineering, and also electronics and software in order to really combine them into instruments.”

HENSOLDT is focused on providing customers with a whole system solution that will address specific challenges. The success of HENSOLDT’s involvement in large and highly complex space projects such as the James Webb Space Telescope has proven its credentials as a leading space sensor provider.

By drawing on this significant experience, HENSOLDT experts are able to work with customers on what is feasible in terms of technical ambition, timeframes and budget, and then partner with them to design and manufacture cutting-edge solutions that perform to high standards in the extreme environments of space.